A Successful Fit: Zane Woolard

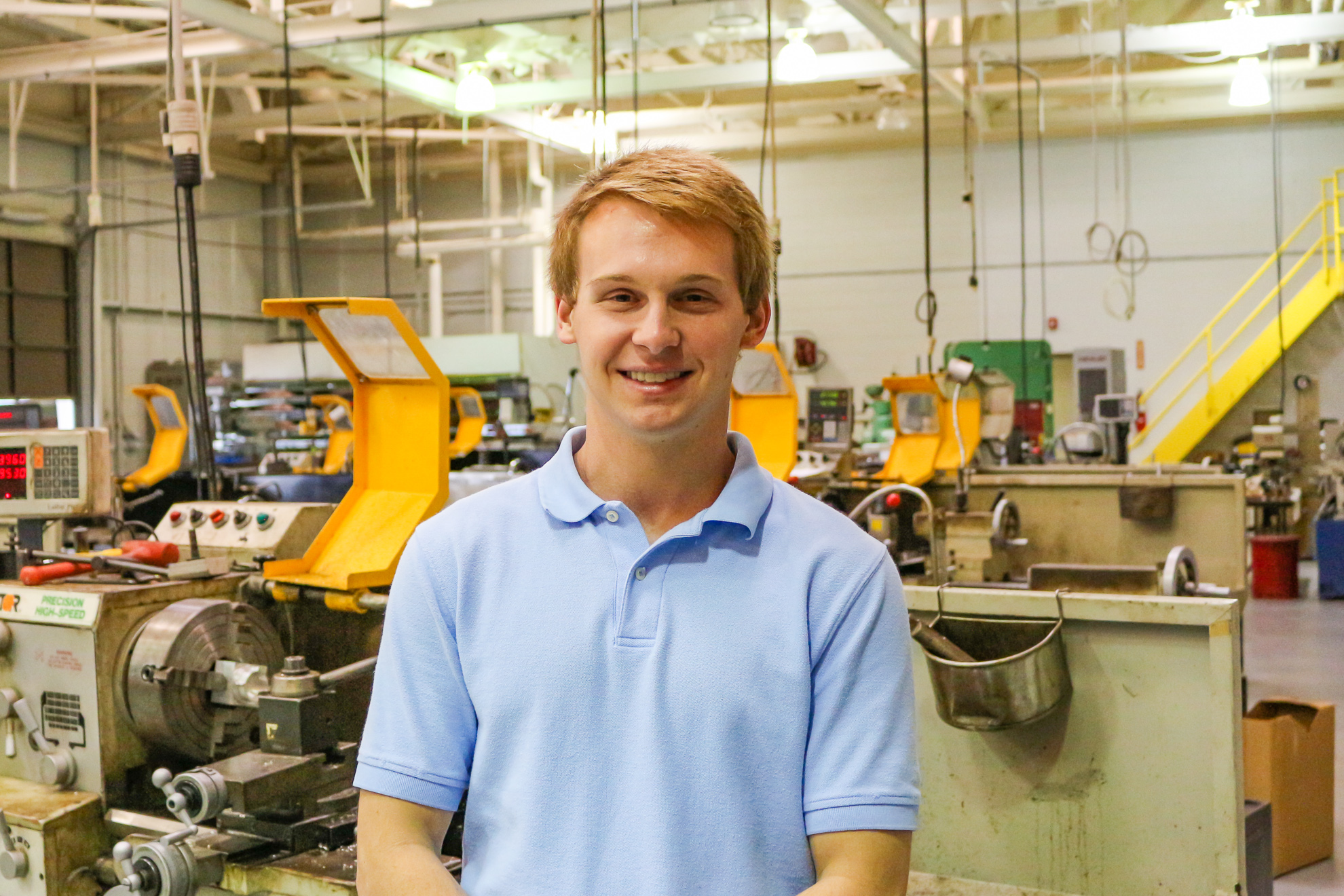

When new parts are designed for machines, they have to meet certain tolerance guidelines. Low tolerance designs have to be machined to the correct fraction of a millimeter or else the parts will not function correctly or they will wear down improperly. All machining does not require this level of specificity. In a similar way, students can approach their career with either a high degree of specificity, and potentially get derailed by small glitch, or have a more open and flexible approach and adapt to changes. Zane Woolard approached Beaufort County Community College with an open mind toward his career, and he found that the mechanical engineering technology program was the place where he fit best.

Woolard considers himself a “homebody” so he wanted to work locally in Beaufort County or commute to a manufacturing companies in Greenville. This way he could stay close to his family and where he grew up. He also likes getting outdoors, kayaking on the Pamlico and camping at a site open to Nutrien employees like his father.

“I like to travel, I like to explore, but I’d like to stay here. I like the simplicity of the area and its laid-back nature,” says Woolard.

His parents left the decision of where to attend college up to him, and he wanted to start somewhere small. “I like the smallness of Beaufort. It’s like we’re family.”

Woolard came to BCCC for an event called “Test Drive Your College”. Every spring, high school students are invited to visit the campus to enjoy food and activities and attend classes they may find interesting. “It set me on Beaufort,” he says. It was here where Woolard met Matthew Lincoln, the former mechanical engineering professor at BCCC.

“I decided that’s what I wanted to do. He was very passionate about what he did,” he says. Woolard had never drafted blueprints in his life, but he says, “I’m a very hands-on type of guy, so running the mills and the lathes, and then the CNC machines, I wanted to learn more about it. When I tried it, I became hooked.”

He had ruled out a couple hands-on programs like welding and electrical engineering from his previous experience and abilities. With a number of manufacturing companies in Beaufort County and surround areas, an associate’s degree in mechanical engineering technology can open up opportunities to work locally. He had grown up learning how to fix cars and lawnmowers, with two handy parents, so the program was a good fit for his skills and goals.

“It can be very overwhelming when you first walk into the shop. You see the machines. You have to know the safety protocol. You have to know the speeds and feeds. You have to know how to set up the machines for each material,” he says.

Woolard excelled in the program, graduating Magna Cum Laude in May. He prefers manual machining over coding. A CNC machine takes a code designed by a technician and uses drill bits and water jets to create the part. Since these machines are capable of machining larger quantities of the same part, Woolard see them being adopted more at larger manufacturers, but he feels confident that there will be an indefinite need for technicians who can machine specific parts. “Manual machining is not going anywhere soon. Sometimes it’s just easier to machine parts in manual mills, as opposed of writing code for a CNC machine.”

In his classes Woolard has made everything from a metallic cut-out of Cape Hatteras Lighthouse to a bearing puller designed by his father. He admits that these things can take a couple of tries, but this is part of the learning process. He eventually got the bearing puller to work, getting closer to the required tolerances of the part.

The tightly-knit mechanical engineering students spend a lot of time together in classes and computer labs, and sometimes these connections follow with them into the workplace. Christopher Leaver, a recent graduate of the college, recently visited campus and told students of openings at his current workplace, which Woolard is pursuing.

This spring, Woolard, as a BCCC ambassador, helped guide high school students to their classes during Test Drive Your College. Among those students may have been the next Zane Woolard: open to a new program that they may never have considered, but one in which they will excel as soon as they begin.